Elliott

Elliott Product Categories

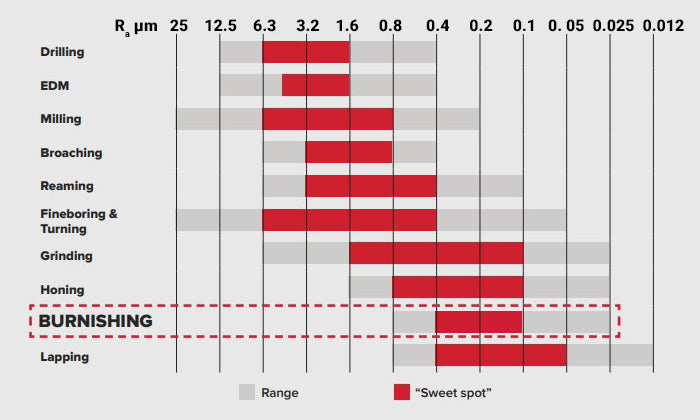

About Burnishing

WHAT IS BURNISHING?

Burnishing is a chipless machining method which cold works the metal without cutting or abrading the surface.

It removes no metal but rather compresses, or “irons-out” the peaks of a metal surface into the valleys, generating a dense and uniform surface.

Roller burnishing improves surface finish and results in dimensional accuracy.

COMPRESSIVE FORCES

The cold working condenses the grain structure of metal, producing an increase in surface hardness from 50% to 100%, within a penetration of 0.25mm to 0.75mm on the part’s surface.

In roller burnishing, the material is elastically deformed to a given depth below the surface. The result is compressive stresses at the surface. In turn, this increases the resistance of the material to fatigue failure because any external forces must first overcome these residual stresses.

BURNISHING REQUIREMENTS

MATERIALS:

Steel, stainless steel, titanium, Inconel, aluminum, brass, bronze, cast iron, ductile iron, other ferrous and non-ferrous materials.

HARDNESS:

Multi-roller burnishing tools up to Rc 45

Carbide-roll & diamond burnishing tools up to Rc 55

PROPER SURFACE PREP:

Turned surfaces of 2-3µm Ra µm are best suited for burnishing applications.

A surface with a peak and valley pattern, without gouges and tears, gives the best burnishing results.