XEBEC Brush™ Surface

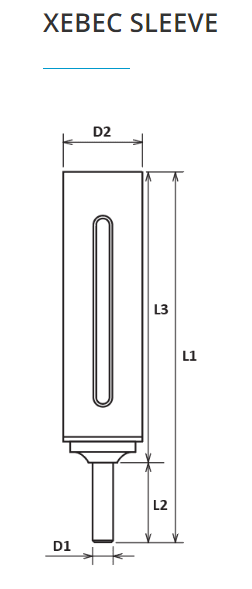

For simultaneous cutter mark removal, deburring, surface finishing and edges. Precise and repeatable cutting tool performance. Tip cutting brushes fit in a sleeve with tool shank for automated deburring in CNC, robots and other machines.

HOW TO SELECT

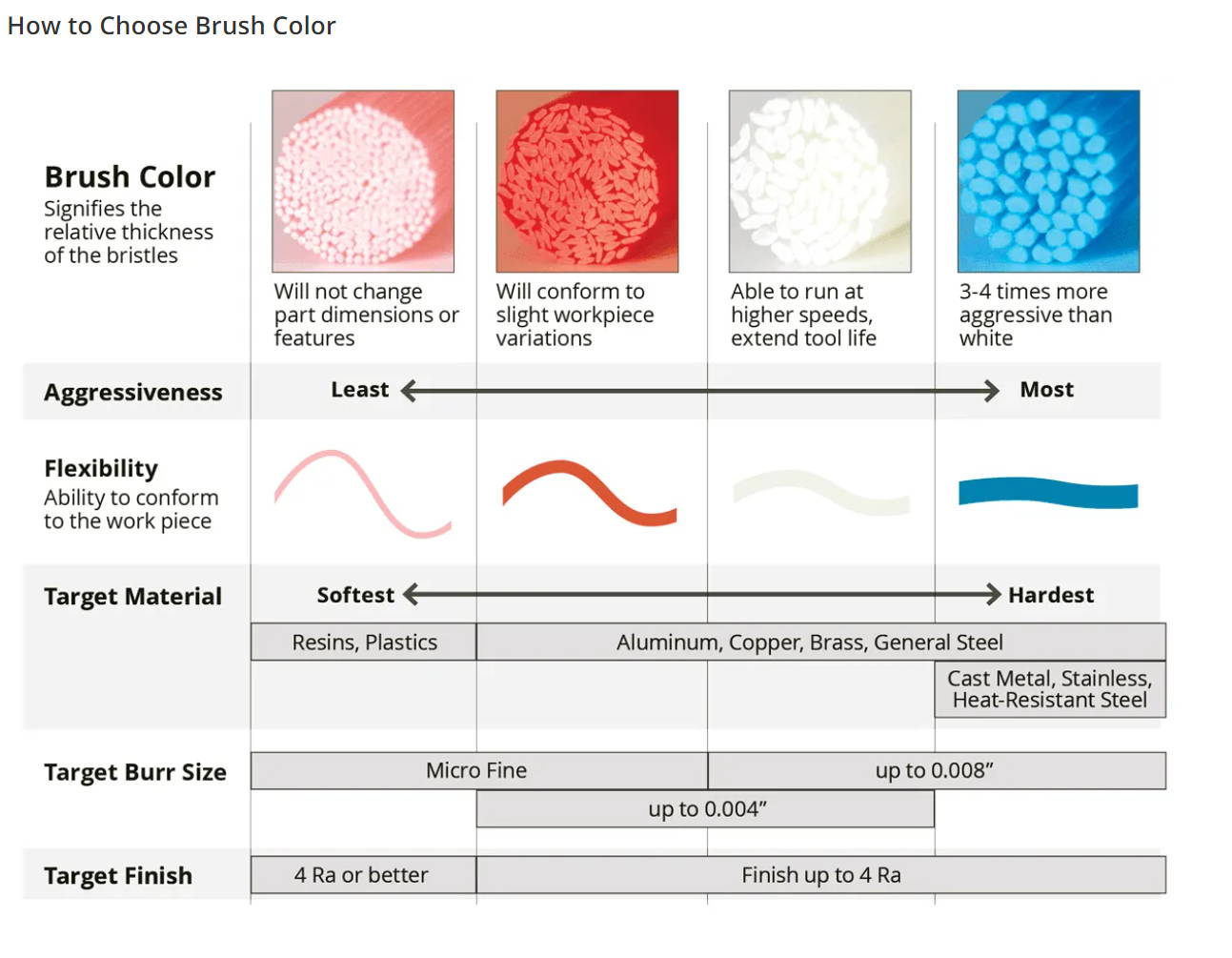

Target Burr Size

Burr Root Thickness of 0.008” or less

(Burrs can be bent with a fingernail)

How to Choose Brush Size

Select a brush size based on workpiece size and shape, interfering objects such as jigs, attachable tool length and cycle time.

It is recommended to use a brush size which is 1.5 to 2 times wider than the width of the surface of the workpiece. This allows the brush to engage the edge at 90 degrees for optimal grinding power. Using a larger brush than the surface width will also require the fewest number of passes and minimize cycle time.