Alberti Angle Heads

Alberti Angle Heads PDF Catalogue (2020)

Alberti Angle Heads PDF Catalogue (2020)

Alberti for Automotive Applications PDF

Alberti for Automotive Applications PDF

Alberti for Aerospace Applications PDF

Alberti for Aerospace Applications PDF

Click Category to go to section

About Alberti

Alberti Angle Heads, made in Italy, are high quality, long life and rigid with exceptional slim design. Both standard and custom sizes and angles are available.

Key Competitive Advantages:

- Body is cast iron which improves thermal stability, rigidity and provides dampening properties

- Monolithic hardened steel spindle input & arbor increases resistance to bending stress by upto 25%. Especially important for extra length angle heads. It also improves balance and makes it possible to reach higher RPM without vibrations.

- Better angle head life from less vibrations and structural integrity.

- Monolithic construction.

- Slim design increases ability to access restricted areas

- Ability for long reach with slim body

- Improved accuracy and concentricity

Alberti Angle Heads Products

Reading Part Numbers

- T90 = 90° Angle Head

- TR90 = 90° Offset Angle Head

- TH = High Pressure Internal Coolant (100 Bar)

- TCU = Adjustable Angle Head

- TA = Fixed 1 angle

- TDA = Fixed 2 angles

- +cn = Arbour Mounted

- no “cn” = Manual Mounted Flange

- 0.4 = ER 8

- 0.5 = ER 11

- 1.5 = ER 16

- 2.5 = ER 25

- 3.5 = ER 32

- 4.5 = ER 40

- 5 = ISO 40

- 100 Bar = 100 Bar Internal Through Coolant

- L = Extra Length

- M = Aluminium

- U = Dual Output

- 🞂 Green = Same as spindle

- 🞂 Red = Opposite to spindle

Click a product diagram image to view a large version

Click here to view new products

T90cn-0.4

Ratio: 1:1

RPM: 10,000 min-1

Max. Axial load: 100 Nm

Torque: 4 Nm

Weight: 4 kg

Collet: E8 Ø 0.5-5 mm

Rotation Direction: 🞂 Same as spindle

T90cn-0.5C

Ratio: 1:1

RPM: 10,000 min-1

Max. Axial load: 150 Nm

Torque: 8 Nm

Weight: 4 kg

Collet: E11 Ø 0.5-7 mm

Rotation Direction: 🞂 Opposite to spindle

T90cn-0.5L

Ratio: 1:1

RPM: 10,000 min-1

Max. Axial load: 150 Nm

Torque: 8 Nm

Weight: 4.3 kg

Collet: E11 Ø 0.5-7 mm

Direction: 🞂 Opposite to Spindle

T90cn-0.5M

Ratio: 1:1

RPM: 10,000 min-1

Max. Axial load: 120 Nm

Torque: 8 Nm

Weight: 2.7 kg

Collet: ERAX-11 Ø 0.5-7 mm

Rotation Direction: 🞂 Opposite to spindle

T90cn-1.5

Ratio: 1:1

RPM: 8,000 min-1

Max. Axial load: 250 Nm

Torque: 15 Nm

Weight: 4.3 kg

Collet: ER16 Ø 1-10 mm

Rotation Direction: 🞂 Opposite to spindle

T90cn-1.5 2U

Ratio: 1:1

RPM: 10,000 min-1

RPM Dry running: 8,000 min-1

Max. Axial load: 250 Nm

Torque: 15 Nm

Weight: 4.3 kg

Collet: ER16 Ø 1-10 mm

Rotation Direction: 🞂 Same as spindle & 🞂 Opposite to spindle

T90cn-1.5L

Ratio: 1:1

RPM: 8,000 min-1

Max. Axial load: 250 N

Torque: 15 Nm

Weight: 5.2 kg

Collet: ER16 Ø 1-10 mm

Rotation Direction: 🞂 Opposite to spindle

T90cn-1.5M

Ratio: 1:1

RPM: 10,000 min-1

RPM Dry running: 8,000 min-1

Max. Axial load: 250 Nm

Torque: 15 Nm

Weight: 2.9 kg

Collet: ER16 (1-10 mm)

Rotation Direction: 🞂 Opposite to spindle

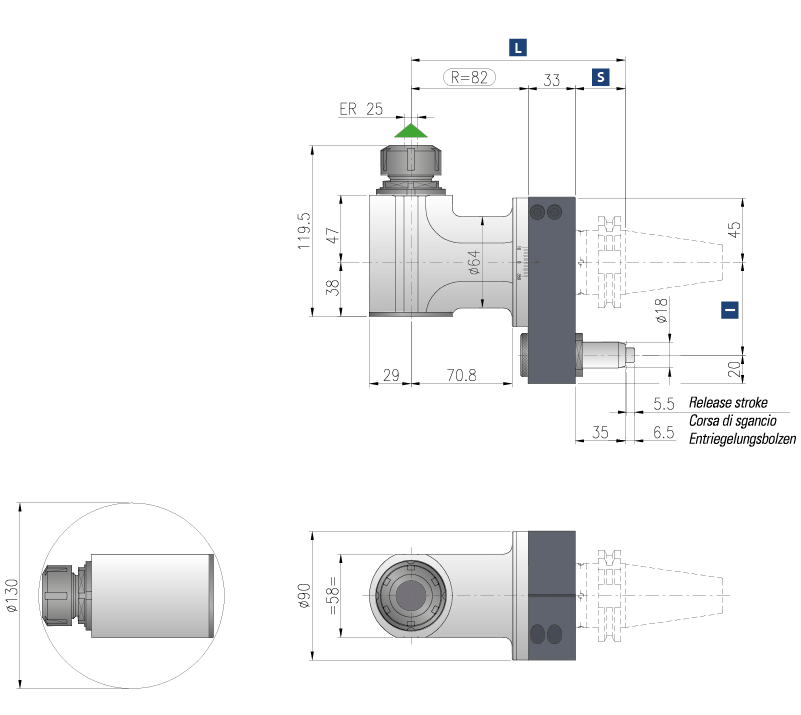

T90cn-2.5

Ratio: 1:1

RPM: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 5.4 kg

Collet: ER25 Ø 1-16 mm

Rotation Direction: 🞂 Same as spindle

T90cn-2.5 2U

Ratio: 1:1

RPM: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 6.4 kg

Collet: ER25 Ø 1-16 mm

Rotation Direction: 🞂 Same as spindle & 🞂 Opposite to spindle

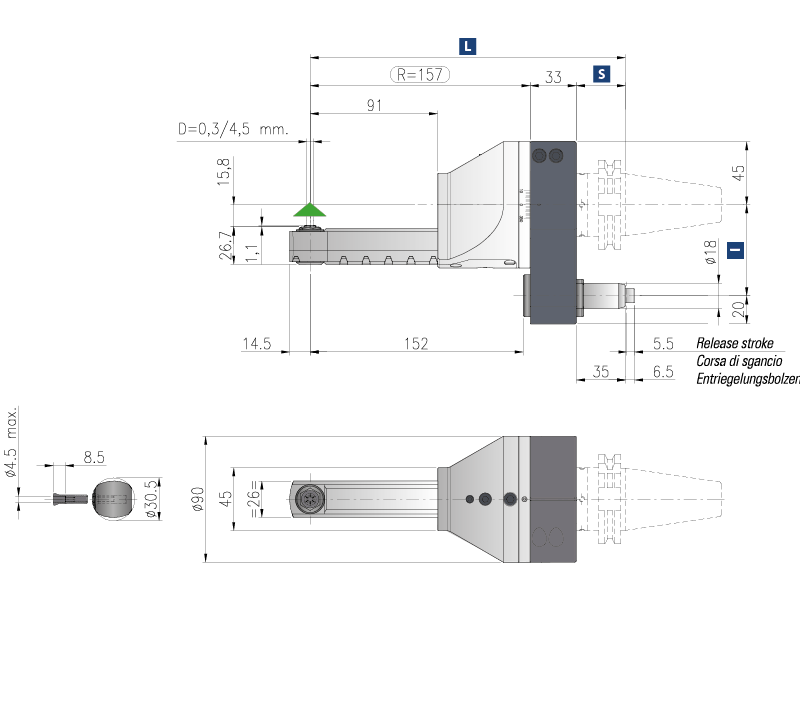

T90cn-2.5L

Ratio: 1:1

RPM: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 6.7 kg

Collet: ER25 Ø 1-16 mm

Rotation Direction: 🞂 Same as spindle

T90cn-2.5M

Ratio: 1:1

RPM: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 4.9 kg

Collet: ER25 Ø 1-16 mm

Rotation Direction: 🞂 Same as spindle

T90cn-3.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 11 kg

Collet: ER32 Ø 2-20 mm

Rotation Direction: 🞂 Same as spindle

T90cn-3.5 2U

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 12 kg

Collet: ER32 Ø 2-20 mm

Rotation Direction: 🞂 Same as spindle & 🞂 Opposite to spindle

T90cn-3.5L

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 13.2 kg

Collet: ER32 Ø 2-20 mm

Rotation Direction: 🞂 Same as spindle

T90cn-3.5M

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 13.2 kg

Collet: ER32 Ø 2-20 mm

Rotation Direction: 🞂 Same as spindle

T90cn-4.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,750 N

Torque: 75 Nm

Weight: 17 kg

Collet: ER40 Ø 3-30 mm

Rotation Direction: 🞂 Same as spindle

TCUcn-0.5

Ratio: 1:1.5 Speeder

RPM: 6,000 min-1

Max. Axial load: 215 N

Torque: 8 Nm

Weight: 2.8 kg

ERAX-11 Ø 0,5/7 mm

ISO 30DIN-69871/BT-30

Rotation Direction: 🞂 Opposite to spindle

TCUcn-1.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 450 N

Torque: 6 Nm

Weight: 4.2 kg

Collet: ER20 ø 1-13mm

Rotation Direction: 🞂 Opposite to spindle

TCUcn-2.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 480 N

Torque: 18 Nm

Weight: 7 kg

Collet: ER25 ø 1-16 mm

Rotation Direction: 🞂 Opposite to spindle

TCUcn-3.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 715 N

Torque: 32 Nm

Weight: 13 kg

Collet: ER32 ø 2-20 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-1.5 100 Bar

Ratio: 1:1

RPM: 10,000 min-1

RPM Dry Running: 8,000 min-1

Max. Axial load: 250 N

Torque: 15 Nm

Weight: 4.5 kg

Collet: ER16 Ø 1/10 mm

Rotation Direction: 🞂 Same as spindle

TH90cn-1.5L 100 Bar

Ratio: 1:1

RPM: 10,000 min-1

RPM Dry Running: 8,000 min-1

Max. Axial load: 250 N

Torque: 15 Nm

Weight: 5.2 kg

Collet: ER16 Ø 1/10 mm

Rotation Direction: 🞂 Same as spindle

TH90cn-2.5 100 Bar

Ratio: 1:1

RPM: 9,000 min-1

RPM Dry Running: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 5.5 kg

Collet: ER25 Ø 1/16 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-2.5L 100 Bar

Ratio: 1:1

RPM: 9,000 min-1

RPM Dry Running: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 6.8 kg

Collet: ER25 Ø 2/16 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-3.5 100 Bar

Ratio: 1:1

RPM: 8,000 min-1

RPM Dry Running: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 12 kg

Collet: ER32 Ø 2/20 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-3.5L 100 Bar

Ratio: 1:1

RPM: 8,000 min-1

RPM Dry Running: 4,000 min-1

Max. Axial load: 1,250 N

Torque: 50 Nm

Weight: 12 kg

Collet: ER32 Ø 2/20 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-4.5 100 Bar

Ratio: 1:1

RPM: 6,000 min-1

RPM Dry Running: 4,000 min-1

Max. Axial load: 1,750 N

Torque: 75 Nm

Weight: 21 kg

Collet: ER40 Ø 3/30 mm

Rotation Direction: 🞂 Opposite to spindle

TH90cn-4.5L 100 Bar

Ratio: 1:1

RPM: 6,000 min-1

RPM Dry Running: 4,000 min-1

Max. Axial load: 1,750 N

Torque: 75 Nm

Weight: 26 kg

Collet: ER40 Ø 3/30 mm

Rotation Direction: 🞂 Opposite to spindle

TR90cn-0.4

Ratio: 1:2.375 speeder

RPM: 8,000 min-1

Max. Axial load: 135 N

Torque: 8 Nm

Weight: 4.5 kg

Collet: Schaublin P6

Rotation Direction: 🞂 Same as spindle

TR90cn-0.5

Ratio: 1:2 speeder

RPM: 8,000 min-1

Max. Axial load: 200 N

Torque: 8 Nm

Weight: 6 kg

Collet: EAX-11 0,5-7mm

Rotation Direction: 🞂 Same as spindle

TR90cn-1.5

Ratio: 1:1,5 speeder

RPM: 8,000 min-1

Max. Axial load: 350 N

Torque: 15 Nm

Weight: 7 kg

Collet: EAX-16 / 1-10mm

Rotation Direction: 🞂 Opposite to spindle

TR90cn-2.5

Ratio: 1:1

RPM: 6,000 min-1

Max. Axial load: 510 N

Torque: 30 Nm

Weight: 7.5 kg

Collet: EAX 25 ø 1-16 mm

Rotation Direction: 🞂 Opposite to spindle

TR90cn-3.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 910 N

Torque: 50 Nm

Weight: 10 kg

Collet: EAX 32 ø 2-20 mm

Rotation Direction: 🞂 Opposite to spindle

TR90cn-4.5

Ratio: 1:1

RPM: 4,000 min-1

Max. Axial load: 1,200 N

Torque: 75 Nm

Weight: 20 kg

Collet: EAX 40 ø 3-30 mm

Rotation Direction: 🞂 Opposite to spindle

New Items

Ultra Slim Series

Alberti Ultra Slim PDF (2021)

Alberti Ultra Slim PDF (2021)

Interchangeable Head Type

Legend

- Interchangeable part

- Coolant nozzle

- Main body

Features

- Interchangeable heads

- Weldon 4 - 5 - 6 mm or M4 output possible

- Possibility of high pressure internal coolant

- Possibility to have the back end mounted at 0° or 180°

- Upper portion easy to replace

- Possibility to supply special cutting tool

Interchangeable Heads

WELDON

5mm

R=7.5mm

H=20mm

WELDON

5mm

R=7.5mm

H=26mm

WELDON

5mm

R=7.5mm

H=33mm

WELDON

4mm

R=6.5mm

H=34mm

M4

R=6mm

H=33.5mm

Interchangeable Upper Type

Legend

- Interchangeable part

- Main body

Features

- Interchangeable upper portion

- Weldon 4 - 5 mm output possible

- 2 different models for milling and drilling

- Upper portion easy to replace

- Possibility to supply special cutting tool

Interchangeable Heads

WELDON

4mm

R=9.5mm

L=79.3mm

WELDON

5mm

R=7.5mm

H=33mm

Index Head

About the Index Head

Alberti Index Head PDF (2021)

Alberti Index Head PDF (2021)

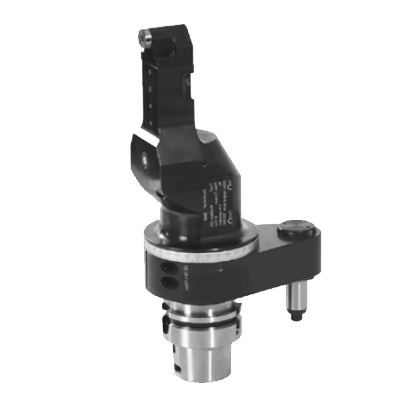

The INDEX head is made of an INDEX module and a selected range of angle head to be combined together. The mechanism inside of the INDEX module is activated by 6 bar air pressure through the reference pin and block and allows the positioning of the output spindle to vary infinitely around 360°. The INDEX head is fully ATC and can reach 10,000 RPM with 10mm max collet.

Extended Heads

Compatible heads and technical details

Alberti Extended Heads PDF (2021)

Alberti Extended Heads PDF (2021)

The extended heads are made up by a portion of extension spacer where it is possible to mount different standard heads.

- T90-0.4

- T90-0.5

- T90-0.5L

- T90-1.5

- T90-1.5L

- T90-2.5

- T90-2.5L

Gallery

Click an image to view a larger version