You have no items in your shopping cart.

Evolute R14F

Evolute R14F Description

High performance 4 flute solid carbide end mills for roughing and finishing

- Square end

- Unequal indexing

- Helix angle 38°

- Chamfer Or Radius

- PVS coating TiAIN

- Diameter tolerance e8

R14F Endmill Part Numbers

| Part Number | Shank | ø D (mm) | ø D1 (mm) | z | APmax | L | Ch/Rad | Coating |

|---|---|---|---|---|---|---|---|---|

| R14F 060R025 TC | Cylindrical | 6 | 6 | 4 | 13 | 57 | 0.25 | TiAlN |

| R14F 080R025 TC | Cylindrical | 8 | 8 | 4 | 16 | 63 | 0.25 | TiAlN |

| R14F 100R025 TC | Cylindrical | 10 | 10 | 4 | 22 | 72 | 0.25 | TiAlN |

| R14F 120R035 TC | Cylindrical | 12 | 12 | 4 | 26 | 83 | 0.35 | TiAlN |

| R14F 160R035 TC | Cylindrical | 16 | 16 | 6 | 32 | 92 | 0.35 | TiAlN |

| R14F 160R035 TC | Cylindrical | 16 | 16 | 4 | 32 | 92 | 0.35 | TiAlN |

| R14F 200R035 TC | Cylindrical | 20 | 20 | 6 | 38 | 104 | 0.35 | TiAlN |

| R14F 200R035 TC | Cylindrical | 20 | 20 | 4 | 38 | 104 | 0.35 | TiAlN |

| R14F 250R050 TC | Cylindrical | 25 | 25 | 6 | 45 | 121 | 0.5 | TiAlN |

R14F Cutting Data

Formula

-

Speed of Cut

-

Spindle RPM

-

Infeed per Tooth

-

Infeed

Notation

- D (mm) - diameter

- z - Number of teeth

- Vc (m/min) - Cutting speed

- fz (mm) - Feed per tooth

- n (1/min) - RPM

- Vf (m/min) - Feedrate

- 𝜋 - 3.1415696

Cutting Data Table

| Material class | Material | Milling | Vc – cutting speed | fz – infeed per tooth [mm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| shoulder | slot | [mm/min] | at D-diameter [mm] | ||||||||||

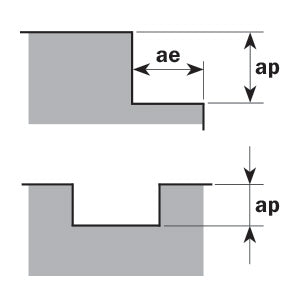

| ap | ae | ap | TiAlN | 6 | 8 | 10 | 12 | 16 | 18 | 20 | 25 | ||

| P | Alloy Steel | 1хD | 0.5хD | 0.5хD | 60-85 | 100-140 | 0.030 | 0.040 | 0.050 | 0.060 | 0.075 | 0.100 | 0.110 |

| P | High alloy steel | 1хD | 0.3хD | 0.4хD | 50-75 | 80-120 | 0.025 | 0.040 | 0.045 | 0.055 | 0.065 | 0.085 | 0.095 |

| M | Free machining stainless steel | 1хD | 0.5хD | 0.5хD | 50-65 | 80-100 | 0.030 | 0.040 | 0.050 | 0.060 | 0.075 | 0.100 | 0.110 |

| M | Midrange stainless steel | 1хD | 0.5хD | 0.5хD | 40-50 | 60-80 | 0.025 | 0.035 | 0.040 | 0.050 | 0.060 | 0.080 | 0.090 |

| M | Tough stainless steel | 1хD | 0.5хD | 0.5хD | 40-50 | 60-80 | 0.020 | 0.030 | 0.035 | 0.040 | 0.050 | 0.065 | 0.070 |

| K | Cast iron | 1хD | 0.5хD | 0.5хD | 60-85 | 100-140 | 0.030 | 0.040 | 0.050 | 0.060 | 0.075 | 0.100 | 0.110 |

| S | Heat resistant steel | 1хD | 0.3хD | 0.3хD | 20-35 | 20-30 | 0.015 | 0.020 | 0.025 | 0.030 | 0.040 | 0.050 | 0.055 |

| S | Titanium | 1хD | 0.4хD | 0.4xD | 15-20 | 30-50 | 0.025 | 0.030 | 0.035 | 0.045 | 0.060 | 0.075 | 0.080 |

| H | Hardened Steel 38-45 HRC | 1хD | 0.3хD | 0.3хD | 50-70 | 80-120 | 0.020 | 0.025 | 0.030 | 0.040 | 0.050 | 0.065 | 0.070 |

| H | Hardened Steel 45-55 HRC | 1хD | 0,2хD | 0,2хD | 40-50 | 60-100 | 0.015 | 0.020 | 0.025 | 0.030 | 0.040 | 0.050 | 0.055 |