CONTACT US TO MAKE AN ENQUIRY

Evolute Endmills

Evolute Endmills PDF Catalogue

Evolute Endmills PDF CatalogueChoose a Category to go to Section

What you need to know about Evolute Endmills

We specialise in high performance solid carbide cutting tools through new milling design technologies, superior material quality & high manufacturing standards.

Below a selection of our endmills, but we have a much larger range available. We hold large stock for fast delivery to you and we are able to do small batch customs on request (click here for form).

Key Take Aways Points

- We are Australian Owned & Australian Made

- We use high grade Austrian Carbide

- We hold large quantity of inventory for fast next day delivery... We know people need tools fast not in 3 weeks.

- Can do Small Batch Custom Endmills

- Can do In-house Necking

Got a question or can't find what you're after... or just want some advice?

Talk to one of our sales reps → Contact us here

High performance Solid Carbide Endmills For Medium to Hard Steels

- End Mills for Hardened steels up to 65 Hrc

- Aerospace titanium alloys and heat resistance steels

- Tool steels and high alloy steels

V14F

- Roughing and Finishing

- Variable Helix for Trochoidal Milling

- Available in 5 Flutes in Short, Medium and Long

- Chip Splitter Option

R14F

- High Performance Roughing

- Rapid Metal Removal

- Atomises Chips, Reduces Power Load

F18F

- Super Finishing

- Helix Angle 80°

- 8 Flutes

H34F

- For Hardened Steel

- Bullnose or Square End

H14B

- For Hardened Steel up to 65HRC

- Ball Nose

High performance solid carbide endmills for Aluminium

- Aluminium and aluminium alloys

- Plastics / Acetal

- Uncoated for Maximum Sharpness

General Purpose Solid Carbide Endmills

- Steels

- Stainless Steels

- Cast Iron

- Non-ferrous Metals

Custom Endmills & Necking

Custom Endmills

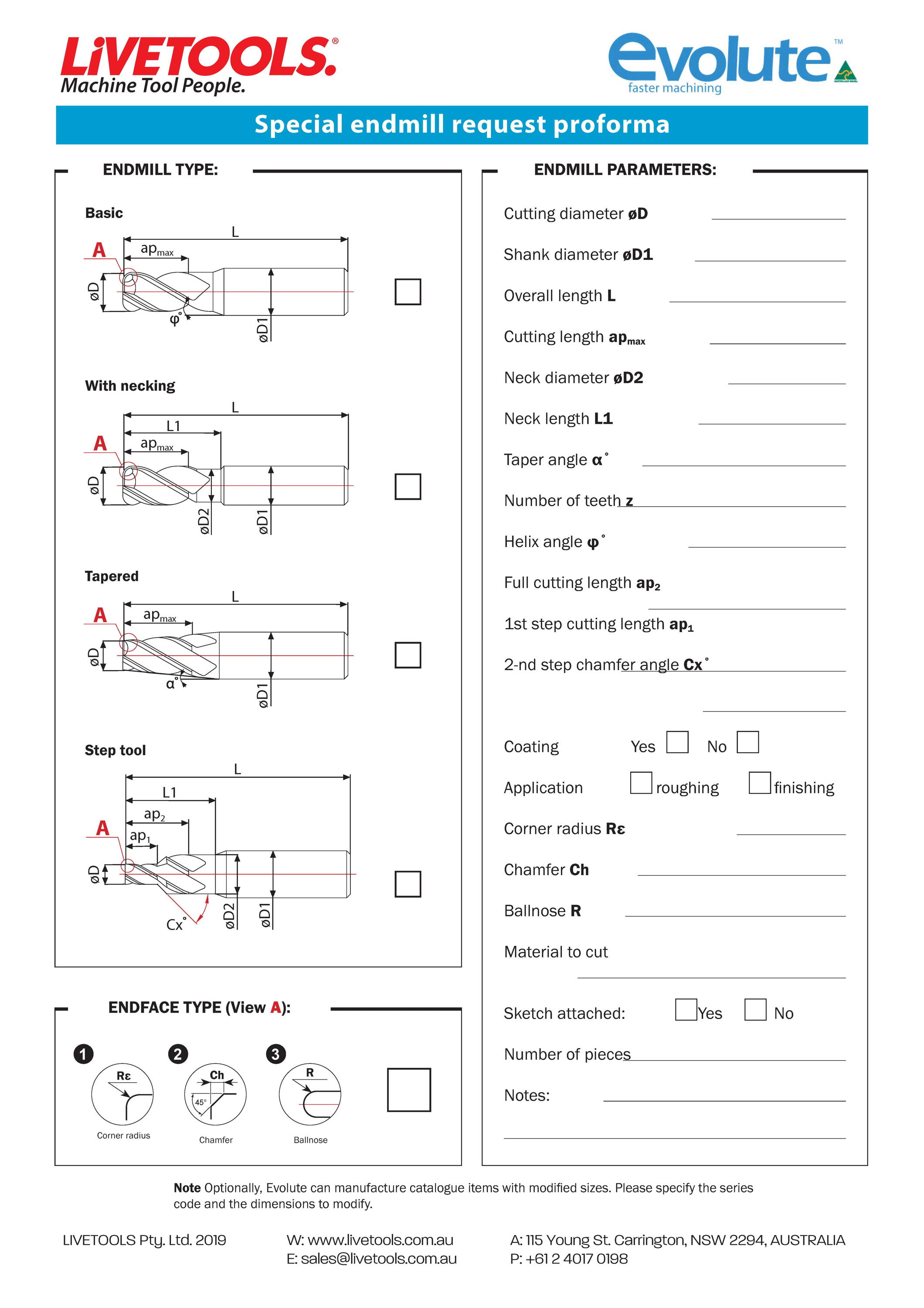

- We can grind small batches of custom or modified endmills designs

- Custom endmills can radically improve productivity and overall cost

- Negotiable Quantities

- Custom Profile Cutters

- Compression Cutters

Custom Endmill ForM

CLICK TO DOWNLOADIn-House Necking

- We have the ability to modify endmills in-house

- Lead time: we can Neck tools typically same day OR next day - eliminating long delays - so say good by to 2 week lead time

- Also we can shorten endmills

- Got an idea for a modification → give us a call

All About Evolute Endmills

We manufacture our endmills in Melbourne, Victoria. We have a number of Walter Grinders and an expert team designing and grinding the endmills.

There is a lot of technology that goes into our endmills and that makes the difference when being used.

But to make great tools, we believe you need to start with high quality materials - for this we import Austrian Carbide. We run the carbide just a little bit softer, which makes it less brittle but means that it blunts a little bit faster. The reason we took this strategy is because typically machine shops break endmills before they wear them out - this way the endmills are more likely to last longer.

GALLERY

Send an enquiry to the Livetools Team or call us on 02 4017 0198